CAPABILITIES

Comoserv has the capacity to offer a wide range of services in accordance with client requirements. We can manufacture over 3,000 tons of industrial equipment per year, producing equipment up to 100 tons each.

L x l x h, thk. = 40m x 4m x 4m, 45mm

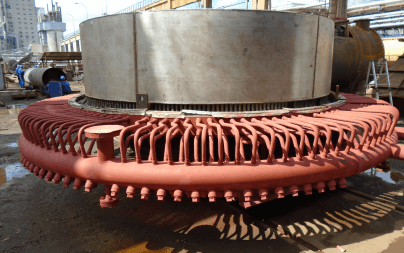

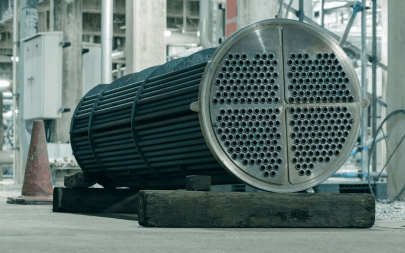

Design and Execution of Industrial Equipment

COMOSERV provides high-quality products, equipped with its own production facilities and advanced testing technologies for the design and execution of a wide range of pressure technology equipment. This includes heat exchangers, process columns and reactors, pressure vessels, evaporators, condensers, tubular sections for air coolers, filters and separators, combustion systems, burner units, incineration packages, modular installations, and fired heaters. We also offer components for both static and dynamic equipment, such as blades and stator parts for gas compressors, rotors for gas compressors, tube bundles, and internal process elements for columns. Our expertise is globally recognized and certified, demonstrated by our consistent delivery of high-quality products to our clients. From the initial design phase to manufacturing and final assembly, our design and execution process for industrial equipment involves close collaboration between engineers and the workforce to ensure optimal performance, safety, and compliance with relevant industrial standards.

Equipment Installation

Equipment installation is one of the most appreciated activities by our clients and an essential part of our company. Therefore, we always offer the best efficient solutions by developing special installation devices tailored to the specifics of each activity. We ensure detailed planning, which includes installation procedures, risk factor identification, and the creation of efficient action plans. Our highly skilled and experienced employees are prepared to manage installation and assembly operations safely and efficiently. Our professionalism and experience allow us to offer a complete range of services, precisely and perfectly adapted to our clients' requirements. Our motto is: "Analysis, planning, completion, control."

Management and Execution of Industrial Turnarounds

For Comoserv, performing periodic overhauls is a natural process that accompanies the company's evolution. We actively engage with our clients to facilitate the use and optimization of their industrial equipment. With vast capacity, we are prepared to act as both a general contractor and a subcontractor in mechanical and piping activities. Over time, we have proven to be a reliable partner for overhauls of various types of equipment, including heat exchangers, process technology columns and reactors, pressure vessels, evaporators, condensers, tubular sections for air coolers, filters and separators, combustion systems, burner units, incineration packages, modular installations, and fired heaters, among others. We also offer solutions for complex repair projects for static and dynamic equipment. Our clients can significantly benefit from these services. Comoserv ensures a wide range of services within periodic industrial turnarounds.

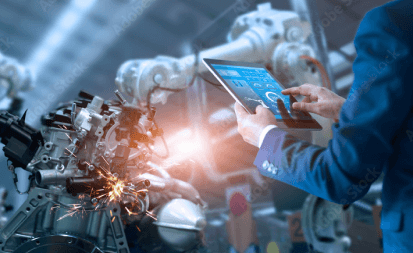

Preventive Maintenance Management

At Comoserv, preventive maintenance management has been integrated into our DNA since our founding. Since our beginnings in 2006, we have been dedicated to serving a wide range of industries through our maintenance management solutions. Over time, we have accumulated extensive experience and continuously improved our technical skills to provide quality services for various industrial installations. We are proud to take full responsibility for operational management (OPEX) for our clients. To this end, Comoserv develops and implements a permanently adapted infrastructure to meet each client's needs. We are committed to offering customized and efficient solutions, contributing to the optimization of equipment operations, and preventing malfunctions.

Turnkey EPC Projects

Our extensive range of services allows us to thoroughly address the specific requirements of each industrial project – from design, procurement, implementation, and assembly to commissioning. This translates into fast, efficient, and economical processes perfectly adapted to the project's requirements. We can provide complete and finished basic engineering. Our service offering begins with the conception process and its implementation. Comoserv Romania is a reliable partner in achieving key projects. With a comprehensive and results-oriented approach, we actively engage in all stages of the project, from planning and design to final delivery.

Pipeline Construction and Installation

Our employees have always stood out for the superior quality of their welding work in the field of pipeline construction. This is just one of the characteristics that set us apart when it comes to pipeline systems for a wide range of industries, nominal diameters, and working media. Our team of pipeline specialists possesses extensive knowledge and practical experience in designing, installing, and maintaining pipelines. Whether it's pipelines for transporting industrial fluids or complex gas and liquid distribution systems, we are ready to manage projects of any size and complexity.

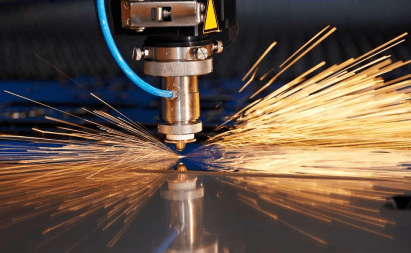

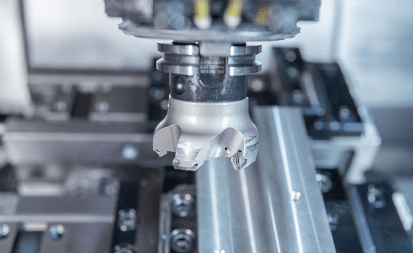

Mechanical Processing

Through advanced processing techniques, including milling, turning, grinding, and others, Comoserv produces precision parts and components tailored to the specific needs of each project.